This is excerpted from Vince Staten’s book, The Unhandyman: Misadventures in Fixing Things. Since it is summer, he thought it would be a good time to tell about his failed attempt at building a boat dock.

The man who is better at his desk, the Unhandyman, should never ever consider building a boat dock.

But there I was in 1975 living on a farm that had a couple of thousand feet of frontage on a large TVA lake. It seemed a shame to let that lake go to waste even if I didn’t own a boat or even a fishing rod.

So I was going to build a boat dock?

I remembered that I had no construction skills either so I did what any college graduate renting a farm fronting on a lake would do.

I engaged a project engineer, someone to be in charge, to design the dock, to plan where each nail goes. And hopefully to drive those nails.

Since I had no budget, I engaged my best friend, Bruce Haney, a graduate of the University of Tennessee’s College of Engineering. O.K., so Bruce was a chemical engineer. He was still an engineer.

Next we needed a plan. So Bruce did some research. He visited other boat docks. He looked up the specific gravity of Styrofoam. He calculated the weight of pine boarding. He figured. And ciphered. He drew. And sketched. And figured some more. He got estimates. And then he brought it over to my farmhouse.

“Here it is,” he said, handing me five pages of plans, including cross-sectional drawings, with little arrows telling what was what.

How much will it cost? I asked, getting to the heart of the matter quickly.

“Well, you got $80 in bolts, and … $200 in lumber … and …”

Stop, I said. I can’t afford a boat dock that costs more than my rent.

So Bruce went back to the drawing board. A week later we had another meeting. This time there were only three pages of plans. And no cross-sectional drawings,

“What we’ve got here,” began Bruce, “is a new concept in boat docks. It’s called ‘cheap.’”

Our next step was to buy the materials. Styrofoam enough for an end-of-the-world floral arrangement. Bolts a foot long. Nails. Washers. Chain. Eye bolts. And, oh yes, lumber.

Now with lumber, you have a choice.

“What kind of lumber would you like?” the helpful salesman asked.

Well, just regular old lumber.

“O.K. do you want fir-pine-oak-fiberboard-plywood-salt-treated-pine-or-what?”

Well, it’s for a boat dock.

“Then you probably want salt-treated pine.”

How much?

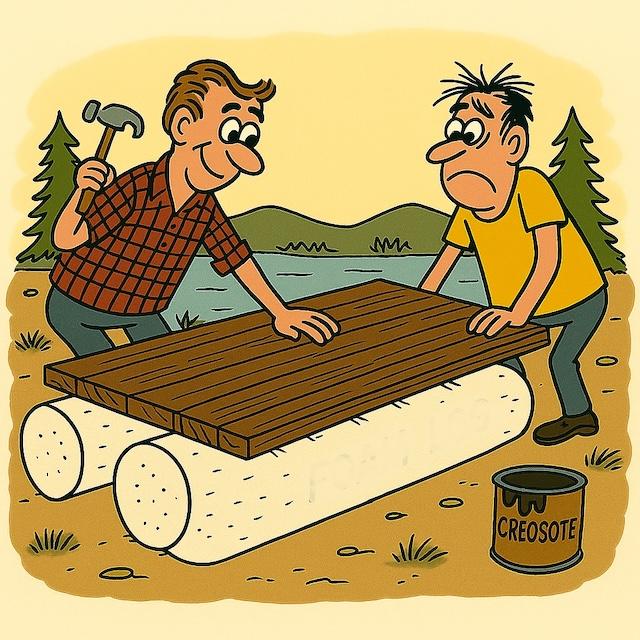

So I settled for regular pine planking and a gallon of creosote. Bruce and I were prepared to build.

Our first task was sawing giant styrofoam logs. The trick with sawing styrofoam is not finding something to cut it – a butter knife will do that. The trick is finding something over 24 inches long to go through the entire width of it. A regular saw won’t do. A bow saw gets hung up on the bow. After Bruce and I had made 17 strategic cuts – none of which connected up – we started looking for a new cutter.

“I wonder if a wire would do it.” Bruce mused.

A hot wire would, I suggested.

“Tell you what,” said Bruce. “If you’ll hold the wire, I’ll stick it in the socket to get it hot.”

While trying to remember the right-hand rule of currents and their fields, it struck me – there’s an old cross cut saw in the garage of my rented farm. I raced over and triumphantly removed it from its dusty moorings. Not noticing that a family of wasps had set up housekeeping on the handle. They were displeased at my attempt at wasp urban renewal and showed their displeasure to my collarbone and my stomach.

Our next step was to creosote the wood for protection against rot. Neither of us had ever done any creosoting before, but we saw no reason why this would matter. We alternated using my one paintbrush – one of us would paint, the other would lead cheers. It was during my second turn that Bruce discovered the warning label on the creosote can: Do not get in contact with skin. Can cause severe burns.

But by this time, we were thoroughly covered with creosote. “Well, it can’t be too dangerous or they wouldn’t let them sell it,” suggested Bruce. We broke up for the night and agreed to meet back bright and early the next morning to complete the “Building of the Boat Dock.”

At seven on Saturday morning, I was awakened by Bruce, who was standing by my bedside.

“Are you dying?” he asked, showing me his red face and arms. “I’m burning up.”

Now that he mentioned it, I did seem to be dying. I went to the bathroom and saw in the mirror that my face was completely red and one eye had swollen shut. Bruce had two good eyes, but his nose was victimized.

We decided that while we were dying, we might as well go ahead and finish the dock. For future generations.

Thus we drilled the wood, nailed on the planks, bolted on the styrofoam and had it ready to put on the lake. Then we remembered. “How are we going to secure it to the shore?” we asked in unison. Bruce, our project engineer, thought and thought.

“I’ve got it,” he said. And then he proceeded to outline something about plumbing fixtures, pipe clamps, threaded steel rods, etc. etc.

We finally settled on rope and luck. We should have settled on chain and a lock. After we shoved the dock in the drink, roped it up and were back at the house, Bruce’s wife, Rosey, came by to see how we were doing (Aside from the creosote burns).

Bruce took her down to display our handiwork, and found two little boys had cut the ropes and had the dock out in the lake paddling around. Five more minutes and all our creosote burns would have been on their way to Rogersville.

Using his best father figure voice, Bruce calmly told the little boys that if they didn’t get the dock back in where they found it, as they found it, he’d make sure their daddies grounded them until the next ice age.

They claimed they thought the dock had just washed up. They put the dock back where it had been (embarrassingly they positioned it better than Bruce and I had) and we retrieved our tools from the house. We extended the ramp and built it around a tree. Bruce said anybody who wanted to steal a boat dock bad enough to cut down a 12-inch-thick tree would probably rather steal a better boat dock.

The Unhandyman: Misadventures in Fixing Things: (Get Bent Press), available on Amazon.

Vince Staten was the longtime columnist of the Louisville Courier-Journal and the New York Daily News. He is the author of 19 books including the best-selling “Did Monkeys Invent the Monkey Wrench: Hardware Stores and Hardware Stories” (Simon & Schuster). He graduated from the University of Tennessee when journalism students used typewriters.